Before starting our article, do not forget to review Durfoam‘s service pages below.

An exploration of the industries that utilize polyethylene foams and their applications in various sectors.

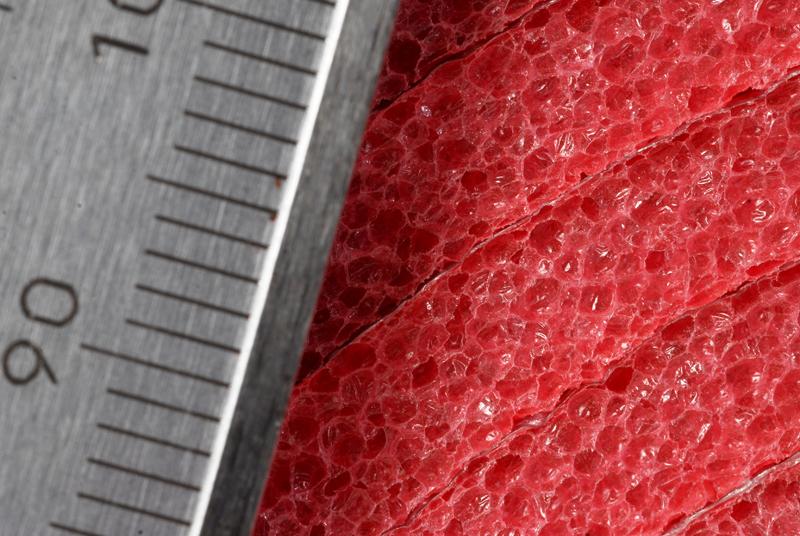

Polyethylene foams are versatile materials that find applications in a wide range of industries. Their unique properties make them valuable in sectors such as construction, automotive, packaging, and more. Let’s take a closer look at some of the sectors that contribute to the use of polyethylene foams.

Construction: In the construction industry, polyethylene foams are widely utilized for insulation, soundproofing, and cushioning applications. These foams provide excellent thermal insulation, helping to maintain a comfortable indoor environment while reducing energy consumption. Additionally, they offer soundproofing properties, minimizing noise transmission between rooms or from external sources. Polyethylene foams also serve as cushioning materials, protecting fragile components during transportation and installation.

Automotive: The automotive industry extensively relies on polyethylene foams for various purposes. These foams are commonly used for impact absorption, reducing the risk of injuries in case of accidents. They also contribute to noise reduction, ensuring a quieter and more comfortable driving experience. Moreover, polyethylene foams provide thermal insulation, helping to maintain optimal temperatures inside the vehicle’s interiors and components.

These are just a few examples of the sectors that benefit from the use of polyethylene foams. Their versatility and unique characteristics make them indispensable in many applications. Whether it’s insulating a building or enhancing the safety and comfort of a vehicle, polyethylene foams play a crucial role in multiple industries.

Construction

Polyethylene foams play a crucial role in the construction industry, offering a wide range of benefits for insulation, soundproofing, and cushioning applications. These foams are lightweight, flexible, and easy to install, making them an ideal choice for various construction projects.

One of the main applications of polyethylene foams in construction is insulation. These foams have excellent thermal properties, helping to maintain a comfortable indoor temperature and reduce energy consumption. Whether it’s insulating walls, roofs, or floors, polyethylene foams provide effective thermal insulation, ensuring energy efficiency and cost savings for building owners.

In addition to insulation, polyethylene foams are also used for soundproofing purposes in construction. The closed-cell structure of these foams helps to absorb and dampen sound vibrations, reducing noise transmission between rooms or from external sources. This is particularly beneficial in buildings where noise control is important, such as residential areas, offices, and educational institutions.

Furthermore, polyethylene foams offer excellent cushioning properties, making them suitable for various construction applications. They can be used to protect fragile materials during transportation or as padding for flooring and walls. The cushioning effect of these foams helps to absorb impact and prevent damage, ensuring the safety of both the building and its occupants.

Overall, polyethylene foams are a versatile and indispensable material in the construction industry. Their ability to provide insulation, soundproofing, and cushioning makes them an essential component in creating energy-efficient, comfortable, and safe buildings.

Automotive

Polyethylene foams play a crucial role in the automotive industry, offering a wide range of benefits and applications. One of the primary uses of polyethylene foams in the automotive sector is impact absorption. These foams are designed to absorb and dissipate energy, providing enhanced safety for vehicle occupants in the event of a collision. By absorbing the impact, polyethylene foams help to reduce the risk of injury and damage to the vehicle itself.

In addition to impact absorption, polyethylene foams are also utilized for noise reduction in automotive interiors. The foams act as excellent sound barriers, minimizing the transmission of noise and vibrations from the engine, road, and other external sources. This helps to create a quieter and more comfortable driving experience for passengers.

Furthermore, polyethylene foams are employed for thermal insulation in vehicle interiors and components. These foams have excellent insulating properties, effectively regulating temperature and reducing heat transfer. By insulating the cabin and various components, polyethylene foams contribute to improved energy efficiency and climate control within the vehicle.

Overall, the extensive use of polyethylene foams in the automotive industry showcases their versatility and importance in enhancing safety, comfort, and efficiency in vehicle design and manufacturing.