In today’s fast-paced world, packaging plays a crucial role in ensuring that products reach consumers safely and efficiently. Have you ever received a package that was damaged during transit? It’s frustrating, right? This is where polyethylene foam comes into play, revolutionizing the way we think about product protection. Not only does it provide exceptional cushioning, but its lightweight nature also helps businesses save on shipping costs. Imagine sending fragile items without the constant worry of breakage—sounds like a dream, doesn’t it?

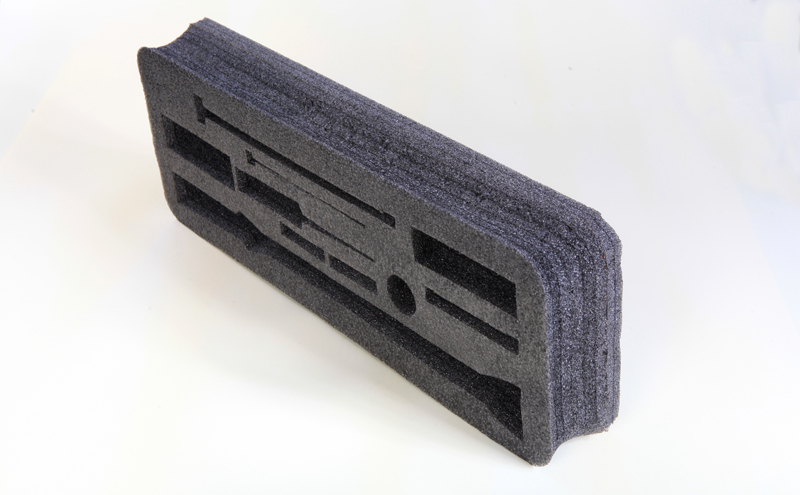

Polyethylene foam is not just about protection; it’s about versatility. Whether you’re in the electronics industry, shipping delicate glassware, or even packaging medical supplies, this foam adapts to your needs. Its unique properties allow for custom shapes and sizes, ensuring that every product is snugly fit and secure. Plus, with rising environmental concerns, polyethylene foam offers a sustainable option that can be recycled, making it a win-win for businesses and the planet alike.

So, why settle for ordinary packaging when you can transform your approach with polyethylene foam solutions? Embrace innovation and protect your products while contributing to a greener future!

Benefits of Polyethylene Foam

Polyethylene foam is a game changer in the world of packaging. Imagine a material that not only protects your products but also saves you money on shipping costs. Sounds like a dream, right? Well, it’s a reality! This lightweight yet durable foam acts as a cushion, absorbing shocks and vibrations during transit. Whether you’re shipping delicate electronics or fragile glassware, polyethylene foam ensures that your items arrive in pristine condition.

One of the standout features of this foam is its resilience. It can withstand various environmental conditions, making it suitable for both indoor and outdoor applications. Plus, it’s resistant to moisture, chemicals, and even UV rays, which means your products are well-protected against the elements. This durability translates to fewer returns and replacements, ultimately boosting your bottom line.

Moreover, the versatility of polyethylene foam cannot be overstated. It can be easily cut and shaped to fit any product, providing a customized packaging solution. This adaptability not only enhances product protection but also improves the overall unboxing experience for customers. Who wouldn’t want to receive their order wrapped in a high-quality, protective layer?

In summary, the benefits of polyethylene foam extend beyond mere protection; it’s about creating a seamless experience for both businesses and customers alike. So, why not elevate your packaging game with this innovative solution?

Applications in Various Industries

Polyethylene foam is not just a packaging material; it’s a game-changer across numerous sectors. Imagine a world where your delicate electronics are cushioned like a baby in a crib! This lightweight yet robust foam is an essential component in protecting products during transit. From electronics to fragile items, its versatility shines brightly. For example, in the electronics industry, polyethylene foam is often used to safeguard televisions, computers, and other sensitive equipment. The foam absorbs shocks and vibrations, ensuring that your pricey gadgets arrive at their destination in pristine condition.

But that’s not all! In the furniture sector, polyethylene foam serves as an excellent protective layer for items like chairs and tables, preventing scratches and dents. It’s also widely utilized in the medical field, where it cushions delicate instruments and devices, ensuring they remain sterile and undamaged. The automotive industry benefits from polyethylene foam as well, utilizing it for packaging parts and components, thereby reducing the risk of damage during shipping.

Here’s a quick look at some key applications:

- Electronics: Protects gadgets during shipping.

- Furniture: Prevents scratches and damage.

- Medical Devices: Ensures safety and sterility.

- Automotive Parts: Reduces risk of damage in transit.

As you can see, polyethylene foam is more than just a protective layer; it’s a vital partner in ensuring that products are delivered safely and efficiently across various industries. The next time you unwrap a new gadget or piece of furniture, take a moment to appreciate the unsung hero that is polyethylene foam!

Sustainability and Environmental Impact

As the world grapples with increasing environmental challenges, the demand for sustainable packaging solutions has never been more pressing. Polyethylene foam stands out as a champion in this arena, offering not only protection for products but also a pathway to greener practices. Its recyclability is a game-changer; businesses can significantly reduce their carbon footprint by choosing foam that can be reused and recycled. Imagine a world where your packaging not only safeguards your products but also contributes to a healthier planet!

Let’s take a small break from our article. Do not forget to review Durfoam‘s service pages below:

Moreover, polyethylene foam is lightweight and durable, which means less energy consumption during transportation. This efficiency translates into lower greenhouse gas emissions, making it a smart choice for companies aiming to enhance their sustainability credentials. By integrating polyethylene foam into their packaging strategies, businesses can:

- Minimize waste through recyclability

- Reduce shipping costs due to its lightweight nature

- Protect fragile items effectively, thus decreasing returns and waste

Ultimately, adopting polyethylene foam solutions isn’t just about packaging; it’s about embracing a responsible future. As consumers increasingly prefer eco-friendly products, companies that invest in sustainable packaging will not only meet market demands but also pave the way for a more sustainable tomorrow.